English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

- Boom Sprayer

- Air Blast Sprayer

- Lawn Mower

- Wheel Rake

- Land Leveler

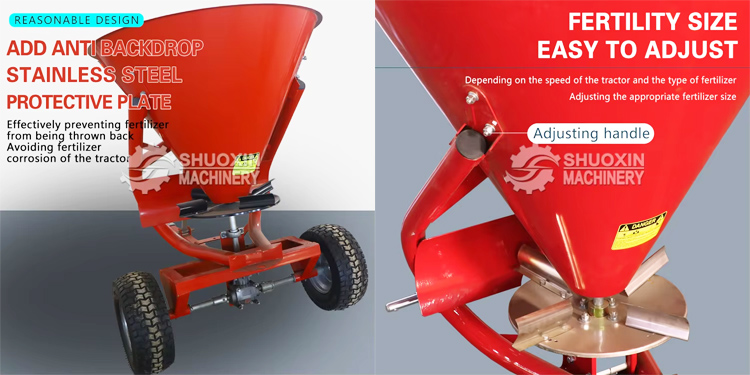

- Fertilizer Spreader

- Manure Spreader

- Seeder Machine

- Agricultural Machinery Transmission Shaft

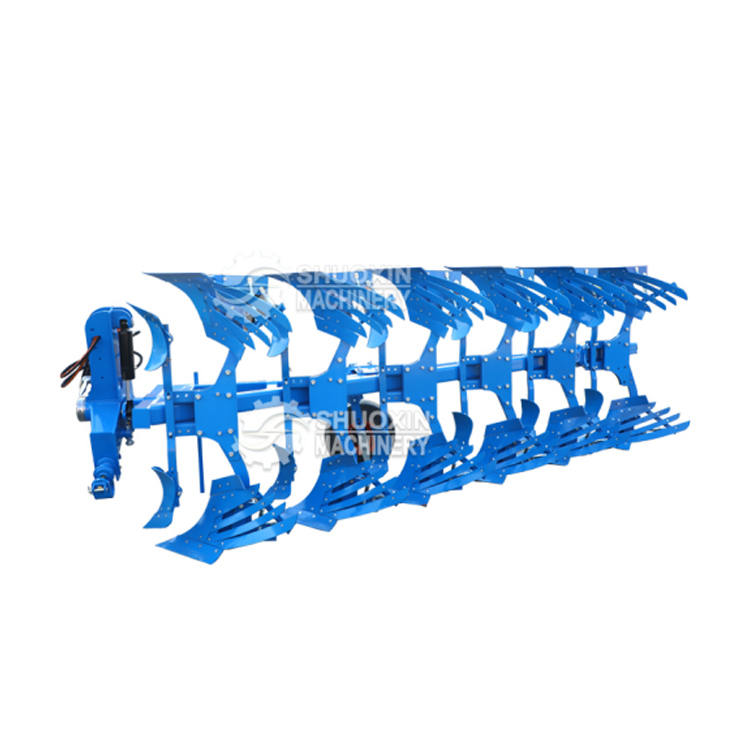

- Plow

- Automatic Roll Tube Sprayer

- Gear Pumps

- Hydraulic Valve

- Bundled Straw Net

- Tractor Flail Mower

- Seedling Killing Machine

- Rotary Rake

- Rake Sun

- Ridging Machine

- Rotary Tiller

3 Point Hitch Spreaders

Send Inquiry

3 point hitch spreaders produced by shuoxin are equipped with an intelligent control system, integrating high-precision sensors, which can monitor key parameters such as soil moisture and fertilizer flow in real time, and automatically adjust the fertilizer amount according to the actual situation, to ensure that each grain of fertilizer can be accurately scattered in the root of the crop, to achieve efficient utilization and reduce waste. At the same time, the intelligent interface is simple and intuitive, and the operation is convenient, even the first time users can quickly get started and easily realize intelligent fertilization.

The 3 point hitch spreaders suspension design not only improves the stability and adaptability of the fertilizer spreader, but also greatly enhances its versatility. The design allows the fertilizer spreader to be easily mounted on various types of tractors, and can be quickly put into operation without complicated installation, greatly saving labor and time costs. In addition, the fertilizer spreader is also equipped with a variety of specifications of fertilizer tray, suitable for different types of fertilizer, to meet the diverse fertilization needs of different crops.

High efficiency and energy saving is another highlight of the intelligent three-point hanging fertilizer spreader. Using advanced energy-saving technology, the machine has very low energy consumption in the operation process, and the noise is properly controlled, and will not cause interference to the surrounding environment.The design of large-capacity fertilizer box reduces the trouble of frequent fertilizer addition and improves the continuity and efficiency of operation.

Main features of Shuoxin 3 point hitch spreaders

3 point hitch suspension stability system: The three-point suspension design, through the tractor rear three mounting points, to ensure that the fertilizer spreader in the process of operation to maintain a high degree of stability, even in the complex terrain can also run smoothly, effectively avoid fertilizer uneven or machine tilt and other problems, to ensure the fertilization effect.

Intelligent fertilization control system: Built-in high-precision sensors and intelligent control modules can monitor soil conditions, crop growth status and fertilizer amount in real time, and automatically adjust fertilization rate and distribution mode through algorithms to achieve accurate fertilization.

Wide and uniform spreading capacity: Equipped with adjustable spreading tray, it can adjust the width and density of spreading fertilizer according to different crops and soil conditions, ensure that the fertilizer evenly covers the whole field, promote the uniform absorption of nutrients by crop roots, and improve the utilization rate of fertilizer.

Large capacity fertilizer storage and automatic metering: with a large capacity fertilizer box, reduce the need for frequent fertilizer, improve work efficiency. The integrated automatic metering system can precisely control the amount of fertilizer applied each time, ensure the accuracy of fertilization, avoid excessive or insufficient, and reduce the waste of resources.

Compatible with a variety of fertilizer types: designed with a flexible fertilizer adaptation device, can easily replace different types of fertilizer tray, suitable for pellet fertilizer, powder fertilizer and other fertilizers, to meet diverse fertilization needs, improve crop growth quality.

Environmental protection and energy saving design: The use of low energy consumption drive system, reduce energy consumption and carbon emissions, at the same time, optimized noise control technology to ensure that the operation process is environmentally friendly, does not affect the surrounding ecology.

How to calibrate the 3 point hitch spreaders?

Calibration weighing system (if equipped) :

Empty the feed box of the fertilizer spreader to ensure that the feed box is empty.

Locate the weighing system calibration device on the fertilizer spreader, usually located under or near the feed tank.

Use an electronic scale or standard weight to calibrate according to the instructions on the calibration device. For example, a standard weight is placed in a material bin and then calibrated by operating a calibration device.

After calibration, confirm that the weighing system display is accurate and error-free.

Adjust the amount of fertilizer:

Locate the fertilizer adjustment device on the spreader, usually located near the outlet or on the control panel of the spreader.

Use a tool such as a screwdriver or wrench to adjust the fertilizer adjustment device according to the amount of fertilizer required. In general, clockwise rotation will increase the amount of fertilizer, counterclockwise rotation will reduce the amount of fertilizer.

In the adjustment process, the amount of fertilizer can be gradually increased or reduced, and tools such as electronic scales can be used to weigh the fertilizer that is spread out in order to grasp the amount of fertilizer more accurately.

Test fertilizer effect:

Select a flat field or test area and apply fertilizer at the normal rate of application.

In the process of operation, pay attention to the distribution of fertilizer, including the uniformity of the fertilizer and the coverage area.

Use tools such as an electronic scale to weigh the fertilizer to ensure that the amount of fertilizer applied is as expected.

It is important to calibrate the drill regularly so that the seeds are spread more evenly and the crops grow healthier. Also, you can avoid wasting seeds or planting too much, which is good for the environment.

Feel free to contact us to make sure your 3 point hitch spreaders are operating at its best performance.Shuoxin can provide valuable insights for optimizing your communication technology and maintaining the life of your equipment.