English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

- Boom Sprayer

- Air Blast Sprayer

- Lawn Mower

- Wheel Rake

- Land Leveler

- Fertilizer Spreader

- Manure Spreader

- Seeder Machine

- Agricultural Machinery Transmission Shaft

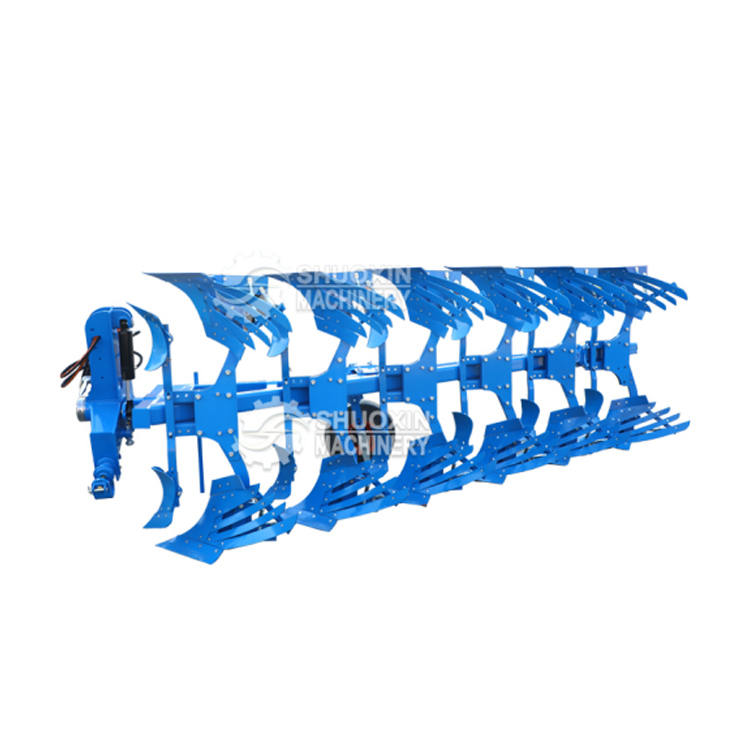

- Plow

- Automatic Roll Tube Sprayer

- Gear Pumps

- Hydraulic Valve

- Bundled Straw Net

- Tractor Flail Mower

- Seedling Killing Machine

- Rotary Rake

- Rake Sun

- Ridging Machine

- Rotary Tiller

Agricultural Machinery PTO Shaft Drive Transmission Shaft

Shuoxin is a leading China Agricultural Machinery PTO Shaft Drive Transmission Shaft manufacturer, supplier and exporter. The products are widely used and are mainly suitable for agricultural tractors, mini-tillers, rotary tillers, seeders, fertilizer spreaders, lawn mowers, balers, lawn mowers, and straw balers.

Send Inquiry

We at Shuoxin offer customized options for agricultural machinery PTO shaft drive transmission shaft to meet the unique needs of our customers. Our products are made of high-quality raw materials, professionally welded, and carefully crafted to forge various types of agricultural machinery transmission shafts. Our agricultural machinery power output shaft transmission shaft is widely used in agricultural tractors, small cultivators, rotary tillers, seeders, fertilizing machines, lawn mowers, balers, lawn mowers, straw balers and other agricultural machinery.

Parameter of Agricultural Machinery PTO Shaft Drive Transmission Shaft

| SERIES | D(mm) | W(mm) | 540min | 1000min | ||||

| Cv | Kw | Nm | Cv | Kw | Nm | |||

| 1S | 22.0 | 54.0 | 16 | 12 | 210 | 25 | 18 | 172 |

| 2S | 23.8 | 61.3 | 21 | 15 | 270 | 31 | 23 | 220 |

| 3S | 27.0 | 70.0 | 30 | 22 | 390 | 47 | 35 | 330 |

| 4S | 27.0 | 74.6 | 35 | 26 | 460 | 55 | 40 | 380 |

| 5S | 30.2 | 80.0 | 47 | 35 | 620 | 74 | 54 | 520 |

| 6S | 30.2 | 92.0 | 64 | 47 | 830 | 100 | 74 | 710 |

| 7S | 30.2 | 106.5 | 75 | 55 | 970 | 118 | 87 | 830 |

| 8S | 35.0 | 106.5 | 95 | 70 | 1240 | 150 | 110 | 1050 |

| 9S | 41.0 | 108.0 | 120 | 88 | 1560 | 190 | 140 | 1340 |

| SERIES | D(mm) | W(mm) | 540min | 1000min | ||||

| Cv | Kw | Nm | Cv | Kw | Nm | |||

| 1S | 22.0 | 54.0 | 16 | 12 | 210 | 24 | 18 | 175 |

| 2S | 23.8 | 61.3 | 27 | 20 | 355 | 42 | 31 | 295 |

| 3S | 27.0 | 70.0 | 33 | 24 | 400 | 50 | 37 | 320 |

| 4S | 27.0 | 74.6 | 38 | 28 | 500 | 60 | 44 | 415 |

| 5S | 30.2 | 80.0 | 47 | 35 | 620 | 70 | 51 | 500 |

| 32S | 32.0 | 76.0 | 53 | 39 | 695 | 83 | 61 | 580 |

| 6S | 30.2 | 92.0 | 55 | 40 | 850 | 83 | 61 | 690 |

| SERIES | D(mm) | W(mm) | 540min | 1000min | ||||

| Cv | Kw | Nm | Cv | Kw | Nm | |||

| 6S | 30.2 | 92.0 | 55 | 40 | 850 | 83 | 61 | 690 |

| 7S | 30.2 | 106.5 | 75 | 55 | 1000 | 106 | 78 | 810 |

| 8S | 35.0 | 106.5 | 90 | 66 | 1250 | 136 | 100 | 1020 |

| 7NS | 35.0 | 94.0 | 70 | 51 | 970 | 118 | 87 | 830 |

| 36S | 36.0 | 89.0 | 90 | 66 | 1175 | 140 | 102 | 975 |

| 42S | 42.0 | 104.0 | 107 | 79 | 1400 | 166 | 122 | 1165 |

CLAMP BOLT

Slide the yoke onto the PTO and insert the bolt and tighten to the correct torque

PLAIN BOREAND SHEAR PIN

Choose the correct shear pin length in such a way as to minimize protrusion.

RA-OVERRUNNING CLUTCH

This device prevents transmission of inertial loads from implement to the tractor during deceleration or stopping of the PTO Keep clear of the implement until all parts have stopped moving. Lubricate every 50hours of use and after storage.

SA-RATCHET TYPE TORQUE LIMITER

This device interrupts the transmission of power when the torque exceeds the setting. Immediately disengage the PTO when ratcheting sounds are heard. Lubricate every 50 hours of use and after storage.

SB-SHEARBOLTTORQUELIMITER

This device interrupts the transmission of power by shearing a bolt when the torque exceeds the setting. Replace the sheared bolt with the same diameter, length and grade as the original. Lubricate the SB with grease fitting at least once every season and after a period of disuse.

FF-FRICTION TORQUE LIMITER

Limits torque transmission to the setting value. Do not change spring compression as this will modify the device setting.

The torque setting is adjusted by increasing or decreasing the height of the springs. To increase/decrease the torque setting tighten/loosen the eight nuts by 1/4 of a turn and check for correct operation. Repeat the procedure if necessary. Avoid excessive tightening of the bolts-implement, tractor, or driveline damage may occur.

Two kinds of plastic safety guard are with the same assembly.

LUBRICATION:

Frequent lubrication is required. Grease the driveline shaft parts at hourly intervals as indicate on the drawing above

DISASSEMBLY:

1. Take a screwdriver to unsnatch the buckle from one to another then to take outside tube apart from plastic cone.

2. Remove the bearing from the groove of the yoke.

3.Repeat the above-mentioned steps for the other side.

ASSEMBLY

1. Assemble the cones with the shields.

2. Grease the groove on the yoke.

3. Slide bearing into groove.

4. Align the bearing on the plastic cover.

SHORTENING THEDRIVESHAFT

Do not recommend any alterations to our Agricultural Machinery PTO Shaft Drive Transmission Shaft. Altering the equipment may cause unsafe conditions and may void the manufacturer's warranty.

1. Remove shielding

2.Shorten the inside and outside drive tubes to the required length. Shorten the drive tubes one at a time by cutting the same length from both inside and outside tubes.

Our Customization Options

We offer customization options to meet the unique needs of our customers. Our experienced engineering team can work closely with you to design and manufacture axial flow pumps that suit your specific application requirements. Please contact us for more information on customization and to request a quote.

Contact Information

Email:mira@shuoxin-machinery.com

Tel:+86-17736285553