English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

- Boom Sprayer

- Air Blast Sprayer

- Lawn Mower

- Wheel Rake

- Land Leveler

- Fertilizer Spreader

- Manure Spreader

- Seeder Machine

- Agricultural Machinery Transmission Shaft

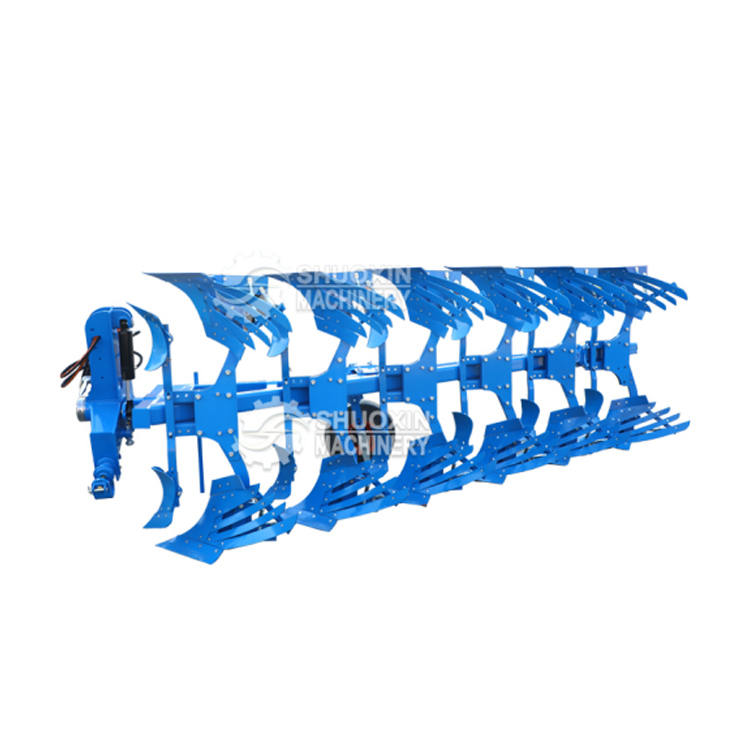

- Plow

- Automatic Roll Tube Sprayer

- Gear Pumps

- Hydraulic Valve

- Bundled Straw Net

- Tractor Flail Mower

- Seedling Killing Machine

- Rotary Rake

- Rake Sun

- Ridging Machine

- Rotary Tiller

Agricultural Orchard Sprayers

Shuoxin is a professional agricultural machinery manufacturer, focusing on providing efficient, intelligent and reliable mechanical equipment solutions for the global agricultural field. Our agricultural orchard sprayers is an important tool for orchard pest control, which can evenly spray the liquid to the fruit trees, improve the control effect.

Send Inquiry

The agricultural orchard sprayers produced by Shuoxin is mainly based on the Bernoulli principle, that is, the pressure is small in the place of high flow rate and the pressure is large in the place of low flow rate. The sprayer compresses air or uses water pressure to produce high-speed water flow, so that the liquid medicine is torn into small water droplets at the nozzle, so as to form a mist and spray onto the fruit tree.

Basic components of agricultural orchard sprayers and its maintenance

Maintenance of storage tank and mixing system

The tank and stirring system form the heart of the sprayer and require careful care to ensure optimum performance. Clean the tank regularly after each use to prevent the buildup of chemical residues, which can lead to contamination and reduce the efficacy of future applications. Appropriate cleaning agents must be used and manufacturer's guidelines followed to avoid damaging the internal coating of the tank. The agitator system is responsible for keeping the mixture even and requires regular inspection of its components, including OARS, propellers or hydraulic jets.

Orchard sprayer maintenance and maintenance

Regular inspection: Regular inspection and maintenance of each component of the sprayer to ensure its normal operation.

Cleaning and maintenance: Cleaning and maintenance should be carried out after each use of the sprayer to prevent the residue and corrosion of the liquid medicine.

Storage environment: Store the sprayer in a dry, ventilated, dark place to avoid moisture and sun.

Maintenance and replacement: The faulty or damaged parts should be repaired or replaced in time to ensure the normal use of the sprayer.

Calibration and performance adjustment

Regular calibration and performance adjustments are key for agricultural orchard sprayers. Calibration ensures accurate product application and minimizes waste and environmental impact by adjusting output volume, pressure Settings and nozzle selection. Performance tuning focuses on optimizing air injection characteristics, adjusting fan speed, air deflector plate and nozzle orientation to improve canopy coverage. Regular performance evaluations, including spray pattern and drift analysis, ensure the sprayer remains effective throughout the season.

Advanced maintenance strategies to extend the life of orchard sprayers

Implement predictive maintenance

The care of agricultural orchards sprayers has been transformed by the use of advanced diagnostic tools that allow real-time monitoring of components. Techniques such as vibration analysis can identify early signs of wear in bearings, pumps and fans, while infrared thermal imaging can detect electrical or friction problems. Oil analysis provides insight into the health of the engine and hydraulic system. These methods help maintain machinery, reduce accidents, optimize performance and extend service life.

Train and operate personnel on best practices

Operator training is key to sprinkler life and performance. It should include principles of technical operation and integrated pest management. Operators must be able to perform routine inspections and recognize early signs of wear. The following best practices for speed and pressure Settings reduce equipment strain. Operators are encouraged to take responsibility for equipment, promoting proactive maintenance and early problem reporting.

If you want to get more information about this agricultural orchard sprayers, you can contact us at mira@shuoxin-machinery.com