English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

- Boom Sprayer

- Air Blast Sprayer

- Lawn Mower

- Wheel Rake

- Land Leveler

- Fertilizer Spreader

- Manure Spreader

- Seeder Machine

- Agricultural Machinery Transmission Shaft

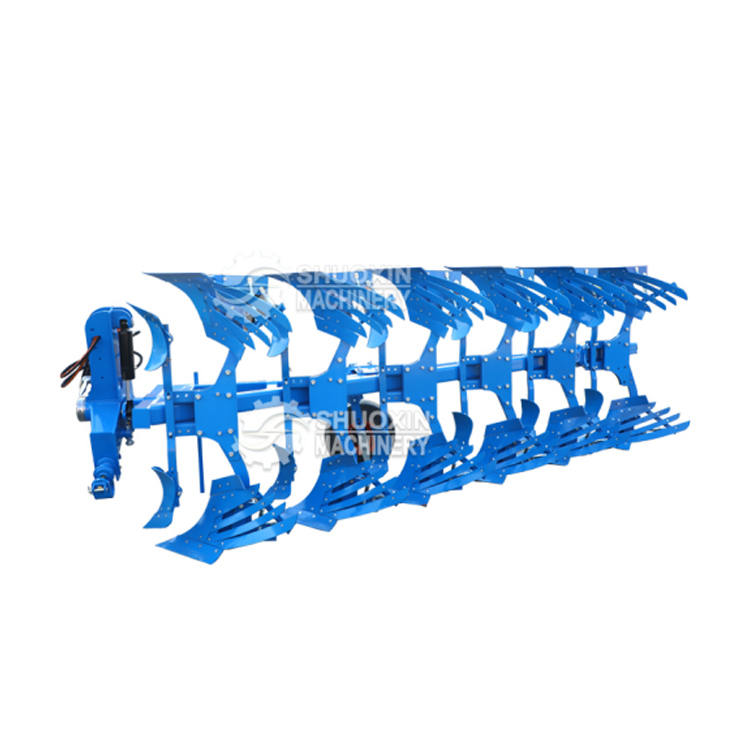

- Plow

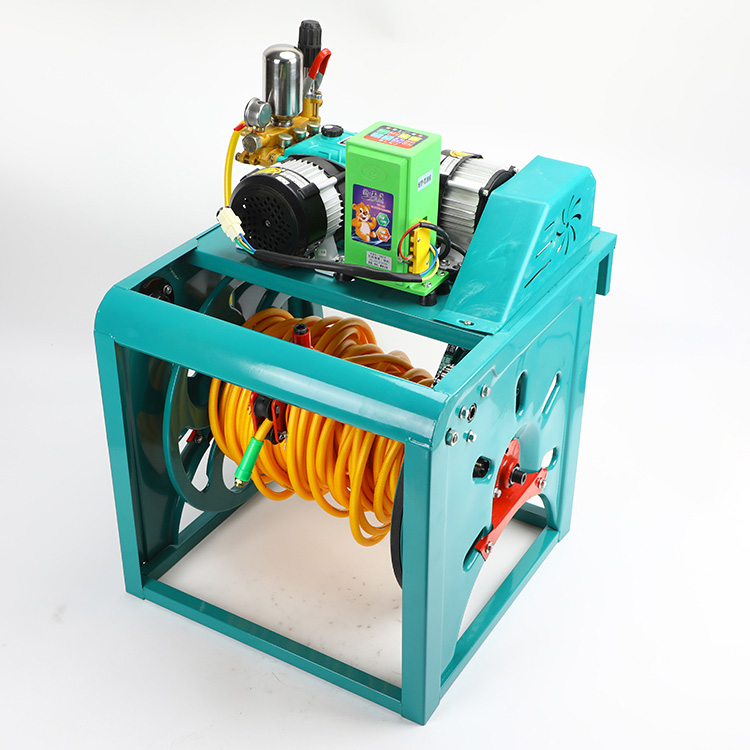

- Automatic Roll Tube Sprayer

- Gear Pumps

- Hydraulic Valve

- Bundled Straw Net

- Tractor Flail Mower

- Seedling Killing Machine

- Rotary Rake

- Rake Sun

- Ridging Machine

- Rotary Tiller

Automatic Tube Sprayer

Send Inquiry

The main structure of the automatic tube sprayer includes the cartridge, the coil device, the propulsion device, the control device and the power supply. These components work together to automate drug spraying.

Automatic tube sprayer draws the cartridge into the pipe through the coil device, and then uses the propulsion device to push the cartridge into the pipe one by one. During the propulsion process, the control device will precisely control the propulsion speed and the amount of medicine to ensure that the drug is evenly sprayed. Finally, the drug is sprayed evenly through the nozzle on the root or leaf surface of the plant.

Characteristics of automatic tube sprayer

High degree of automation: Automatic tube sprayer can automatically complete the tube rolling, advancing and spraying process of the drug, which greatly reduces the tedious and labor intensity of manual operation.

High efficiency: Due to the high degree of automation, the automatic tube sprayer can quickly complete a large area of spraying work, improving the efficiency of the operation.

Less drug use: By precisely controlling the amount of drug and spraying speed, the tube applicator can reduce drug waste and reduce production costs.

Flexible adjustment: The automatic tube sprayer can adjust the dosage and speed according to different plant and environmental needs to achieve the best spraying effect.

Application of automatic tube sprayer

Automatic tube sprayer is widely used in various fields of agriculture, forestry, garden and urban greening. It is especially suitable for orchards, farmland, flower beds, tea gardens and other places that need to spray drugs in a large area

Operation and maintenance

Operation: In the operation of the automatic tube sprayer, it is necessary to follow the requirements of the manual.Automatic tube sprayer usually includes checking before starting up, adding gasoline and liquid medicine, starting and stopping the machine, and spraying.

Maintenance: Regular maintenance and maintenance of the pipe applicator is the key to ensure its long-term stable operation. This includes checking the connection of various components, cleaning nozzles, replacing damaged parts, etc.