English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

- Boom Sprayer

- Air Blast Sprayer

- Lawn Mower

- Wheel Rake

- Land Leveler

- Fertilizer Spreader

- Manure Spreader

- Seeder Machine

- Agricultural Machinery Transmission Shaft

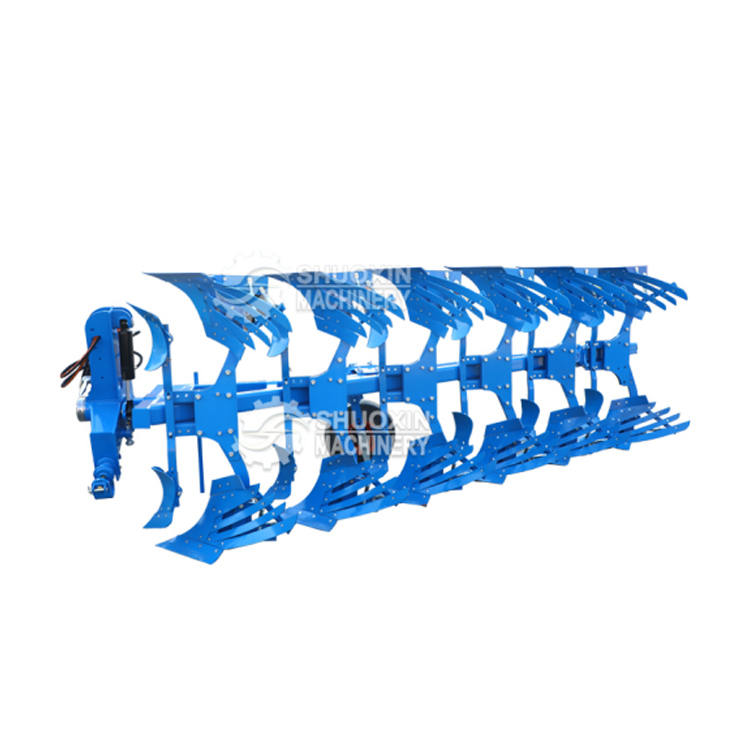

- Plow

- Automatic Roll Tube Sprayer

- Gear Pumps

- Hydraulic Valve

- Bundled Straw Net

- Tractor Flail Mower

- Seedling Killing Machine

- Rotary Rake

- Rake Sun

- Ridging Machine

- Rotary Tiller

Grain Seeders

As a professional manufacturer of grain planter, the grain seeders we produce is a modern agricultural machinery that integrates sowing, fertilization, soil covering, suppression and other functions,using advanced precision seeding technology, it can adapt to different soil types and crop planting needs.

Send Inquiry

Shuoxin grain seeders are set of sowing, fertilization, soil covering, suppression and other multi-functional in one of the modern agricultural machinery. Using advanced precision seeding technology, it can adapt to different soil types and crop planting needs, and is widely used in wheat, corn, soybean, rice and other grain crops sowing operations. The machine has the advantages of compact design, reasonable structure and simple operation, which is suitable for large-scale farm operation and fine planting of small plot family farm.

The working principle of grain seeders mainly includes seed supply, sowing control, fertilization, soil cover suppression and other key links:

Seed supply: The seeds are stored in the seed box and enter the sowing device by gravity or suction. The precision planter distributes seeds evenly into each sowing hole according to the preset sowing amount.

Seeding control: The intelligent control system precisely controls the opening and closing of the seeder according to the GPS signal and preset seeding parameters to ensure that the seeds are placed at the correct position and time.

Fertilization:The fertilization device will evenly spread the fertilizer under or on the side of the seed according to the set amount of fertilizer, providing the necessary nutrients for crop growth.

Soil cover suppression: The soil cover device covers the seed with soil to protect the seed from the external environment; The suppression wheel compacts the soil and promotes close contact between the seed and the soil, which is conducive to seed germination and root growth.

How to set seed rate on grain seeders?

Setting the right seed rate on the grain seeders are crucial for achieving optimal crop yields. A proper seed rate helps farmers avoid over-seeding or under-seeding, both of which can impact crop density and productivity. This guide walks you through the key steps and considerations for setting the seed rate on a grain drill to help ensure effective planting.

Maintenance of shuoxin grain seeders

Regular inspection: Regular inspection of the transmission parts, bearings, chains, etc., to ensure good lubrication, no loosening, wear phenomenon.

Cleaning and maintenance: After each operation, clean the soil, weeds and other debris on the seeding machine in time to keep the equipment clean to avoid corrosion and blockage.

Lubrication maintenance: According to the requirements of the manual, regularly lubricate each lubrication point to keep the equipment flexible operation.

Storage management: In non-working season, the seeder should be stored in a dry and ventilated warehouse to avoid direct sunlight and rain to ensure that the equipment is in good condition.

Professional training: Operators should receive professional training and be familiar with the structural principle, operation method and safety specifications of the seeder to ensure safe and efficient operation.

The grain seeders are really good agricultural aid,it can not only plant the seeds, but also fertilize them while planting, cover the soil after planting, and gently press down, all of which can be packed in one machine. Moreover, it is particularly accurate in sowing, no matter what kind of land, what kind of crops, it can cope with. Wheat, corn, soybeans, rice, these grains, grain seeders can grow easily. Its appearance is also very small, the structure is arranged very reasonably, and it is particularly easy to use. Therefore, whether it is a large farm or a small field at home, you can rely on it to grow fast and well.