English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

What are the differences between agricultural satellite graders and laser graders

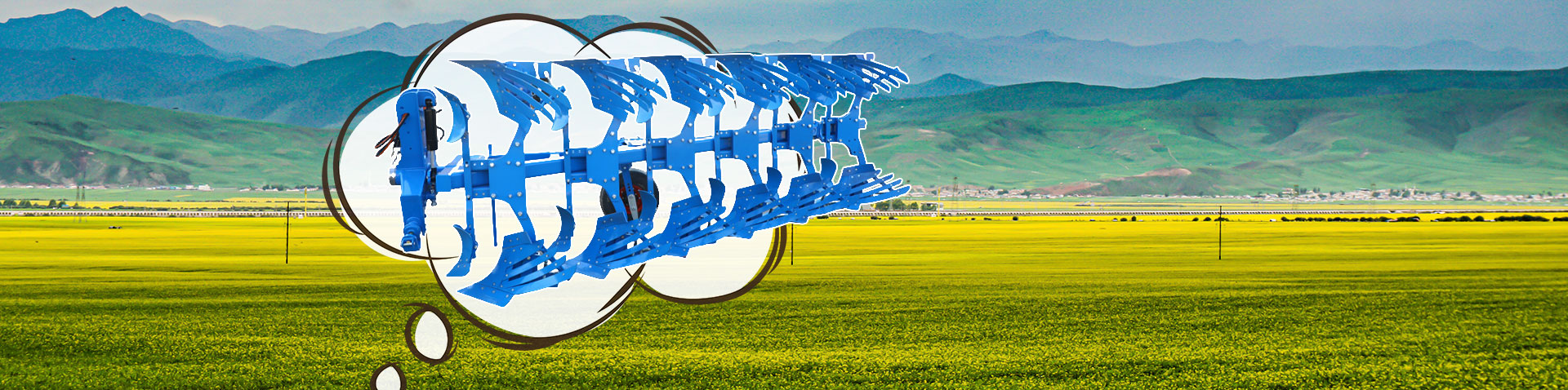

Satellite graders and laser graders are commonly used equipment in agricultural production for land leveling and cultivation. Although their purposes are the same, their working principles and usage methods are different. Shuoxin Machinery provides a detailed introduction to the differences between agricultural satellite graders and laser graders in terms of basic principles, work efficiency, applicable scenarios, and technical characteristics.

1. Basic principles

Satellite land levelers use the signal positioning of GPS satellites to measure the plane and elevation. In agricultural production, satellite land levelers have greater applicability in land consolidation and emissions. When using GPS signals as positioning standards, higher horizontal forces, higher planes, and higher efficiency can be achieved, and the current position of the equipment can be analyzed and recorded through signal analysis, making the measurement of planes and elevations more accurate and precise.

Laser grader is a device that uses laser measurement technology to measure and level the height. It is mainly used in agricultural production for the production of rice paddies, orchards, greenhouses, and the leveling of water-saving projects in farmland. It can emit precise laser signals, measure height differences, automatically adjust its position to achieve uniformity of height and preset height.

2. Work efficiency

In terms of work efficiency, satellite graders and laser graders have higher efficiency and flexibility. They can perform multiple tasks simultaneously and complete large-scale land leveling and cultivation. On the other hand, laser graders have high work efficiency and are suitable for leveling small areas of land that require high levels.

3. Applicable scenarios

Satellite graders are suitable for deep development and soil consolidation and discharge on a larger scale, such as leveling roads, large beaches, docks, and ports, as well as waste landfill treatment and site leveling. However, the application scenarios of laser graders are more extensive in agricultural production, with a greater majority being applied to the leveling and discharge of water-saving projects in paddy fields, orchards, and farmland.

4. Technical characteristics

Satellite graders have more precise technical characteristics and usage, requiring high-precision measurement and processing of external signals to achieve lower errors and higher reliability. It has a relatively flexible digital control technology, which can achieve accuracy calculation and displacement adjustment of the entire process with computer assistance.

The laser leveling machine adopts laser measurement technology and digital control technology, which is more precise in leveling and height measurement and has a wider range of applications. The digital control system used in laser graders can help adjust module width, excavation depth, tool up and down condition, position and speed in a timely manner, and can achieve high-precision adjustment and quality inspection. Laser graders are more accurate in height measurement and leveling compared to satellite graders, ensuring work quality.

Although satellite graders and laser graders are commonly used equipment in agricultural production, there are differences in their basic principles, work efficiency, applicable scenarios, and technical characteristics. In practical applications, the equipment used should be combined with factors such as the land being processed, the size of the farmland, soil conditions, and project requirements, and comprehensively consider selecting the most suitable leveling machine for oneself.