English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

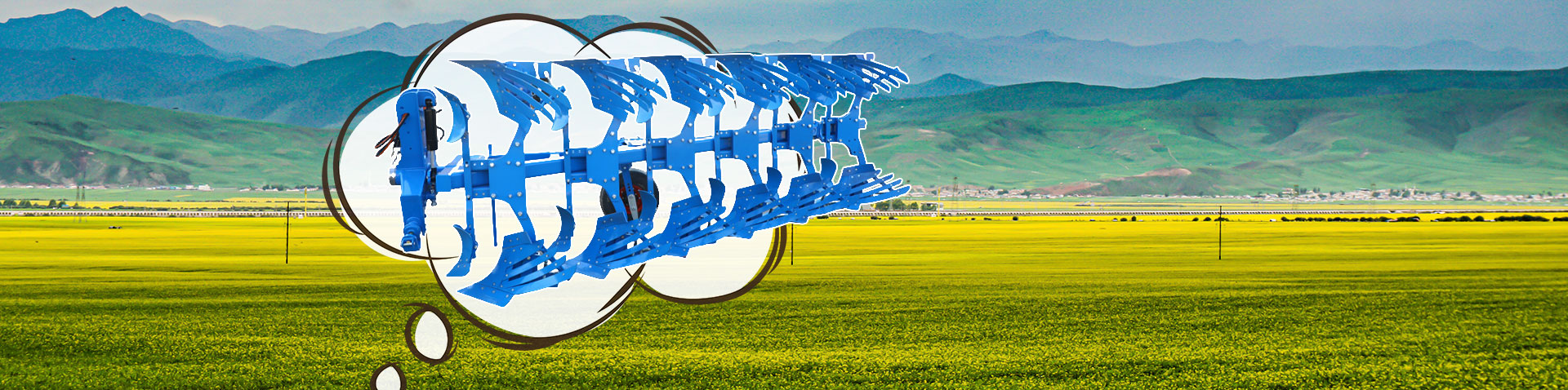

Care and maintenance of boom sprayers

2024-07-18

Boom sprayer is mainly composed of spray gun, spray rod, liquid system, reflux system, electrical control system, the following is the maintenance and maintenance of the equipment:

Adhere to daily maintenance. Clean up the debris accumulated in the sterilization machine in time to avoid clogging; do not let the spray liquid leak into the wire to avoid moisture or short-circuit of the equipment.

Perform regular maintenance on the equipment. Timely check the boom, spray rod, pump and other important parts of the problem, clean or replace the nozzle, spray gun, sealing ring and other wearing parts.

Ensure that the liquid circuit system works properly. Replace the filter regularly to avoid the pump being blocked by debris, otherwise it will affect the spraying effect and shorten the life of the equipment.

Check the electrical control system. Regularly check whether the wiring of wires and electrical equipment is normal, whether the power switch is powered on, whether the sensor is working normally, and whether the equipment has an early warning function.

Regular maintenance of the hydraulic system: clean the hydraulic tank, take anti-rust and dehumidification measures to avoid aging hydraulic components, and avoid oil leakage and oil stains affecting the use effect and environment.

In short, in order to extend the service life of the boom sprayer, it is necessary to pay attention to daily maintenance, regularly check the normal of the liquid circuit and electrical system, and timely deal with existing problems to ensure the performance and stability of the equipment. If you encounter more complex problems, you can ask professional maintenance workers to repair or maintain.