English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

- Boom Sprayer

- Air Blast Sprayer

- Lawn Mower

- Wheel Rake

- Land Leveler

- Fertilizer Spreader

- Manure Spreader

- Seeder Machine

- Agricultural Machinery Transmission Shaft

- Plow

- Automatic Roll Tube Sprayer

- Gear Pumps

- Hydraulic Valve

- Bundled Straw Net

- Tractor Flail Mower

- Seedling Killing Machine

- Rotary Rake

- Rake Sun

- Ridging Machine

- Rotary Tiller

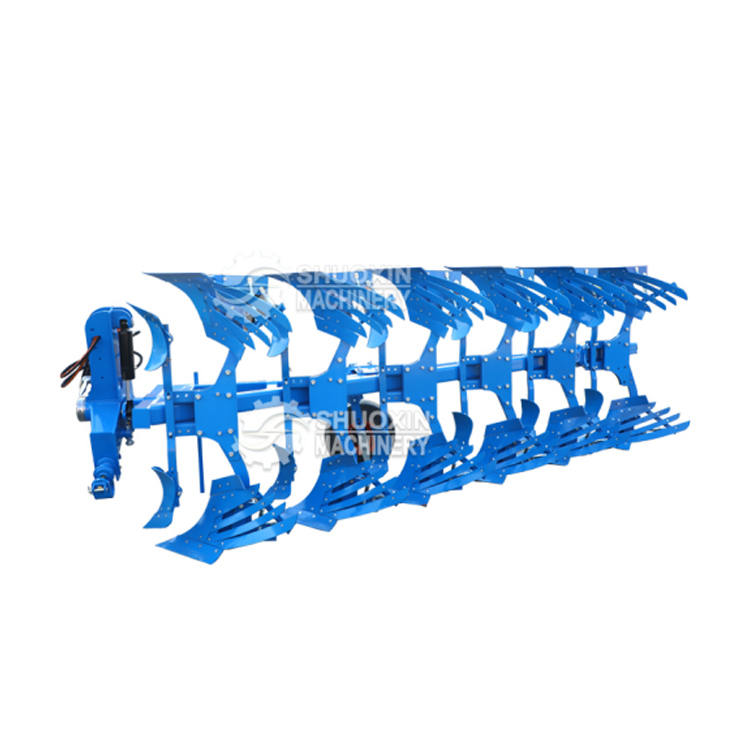

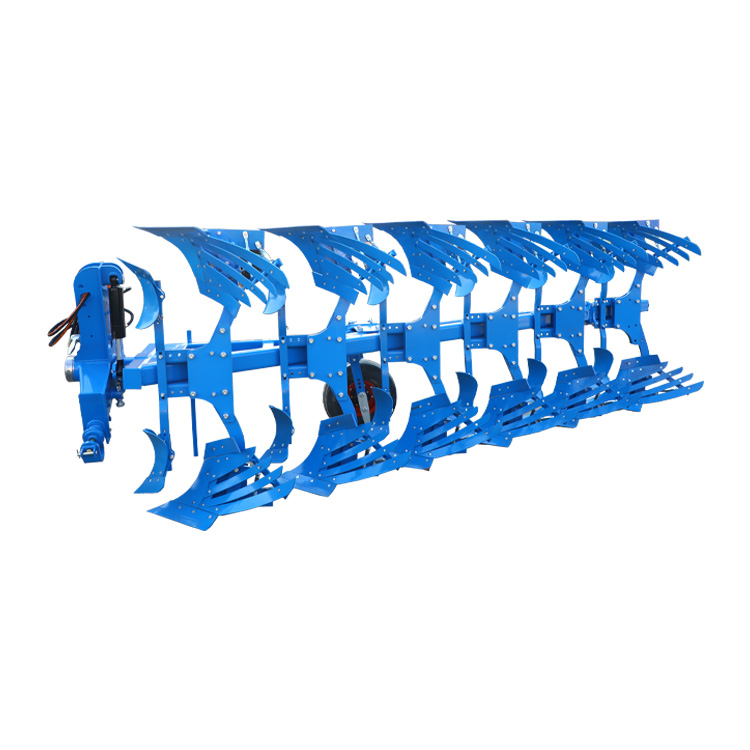

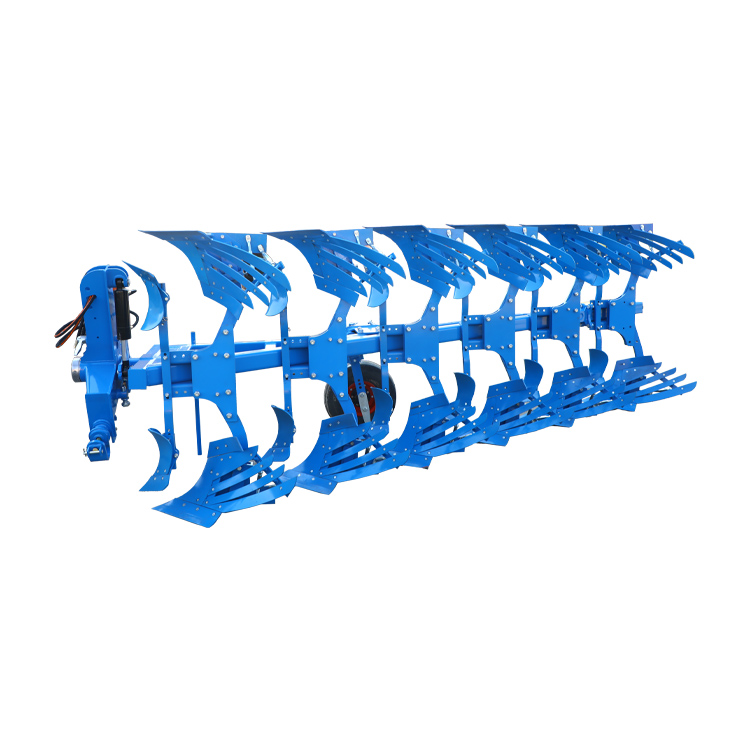

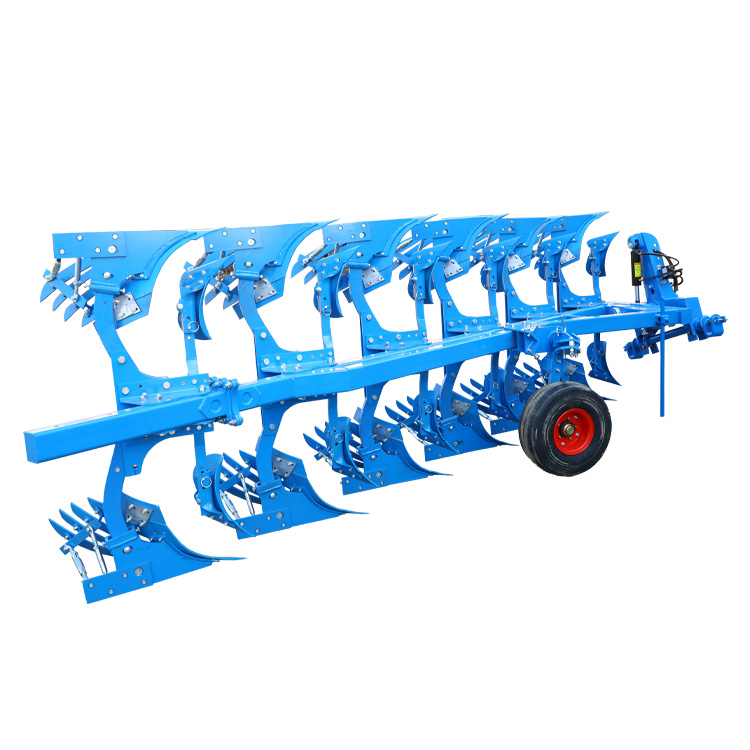

Reversible Plow

Send Inquiry

The reversible plow produced by Shuoxin is the ideal choice for farmers looking for a versatile and efficient farming solution. This agricultural equipment is an important tool for crushing and smoothing the soil before sowing. Our reversible plows are designed to provide precision and speed of work, making it easier for farmers to achieve their yield goals.

Understand the basics of reversible plows

Definition and use of reversible plow

Plow is a practical agricultural machine that can turn the soil in both directions, allowing continuous tillage without the need to lift the tool at the end of each furrow, saving time and increasing productivity and reducing soil compaction. Reversible plows are especially useful in undulating terrain, where a conventional one-way plow may have difficulty maintaining consistent furrow depth and width.

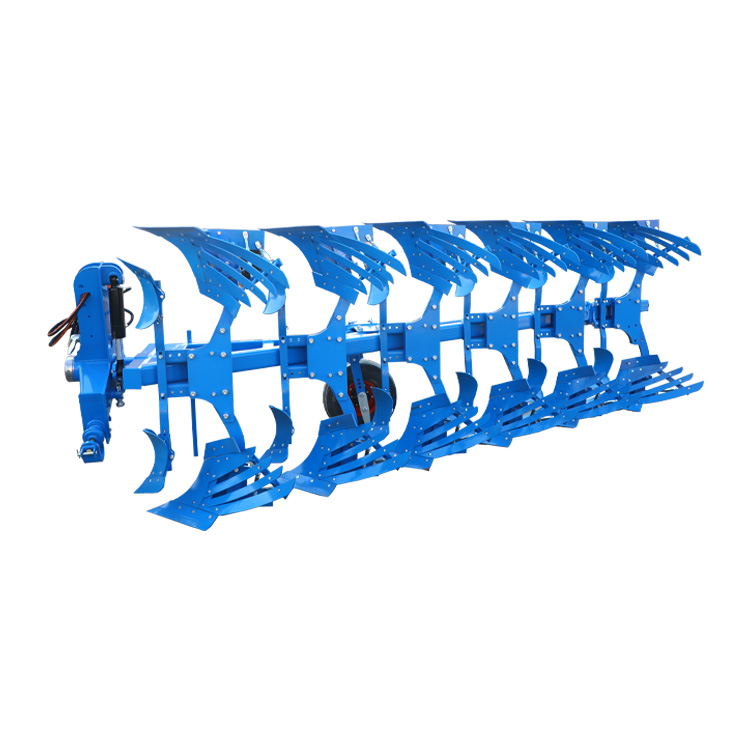

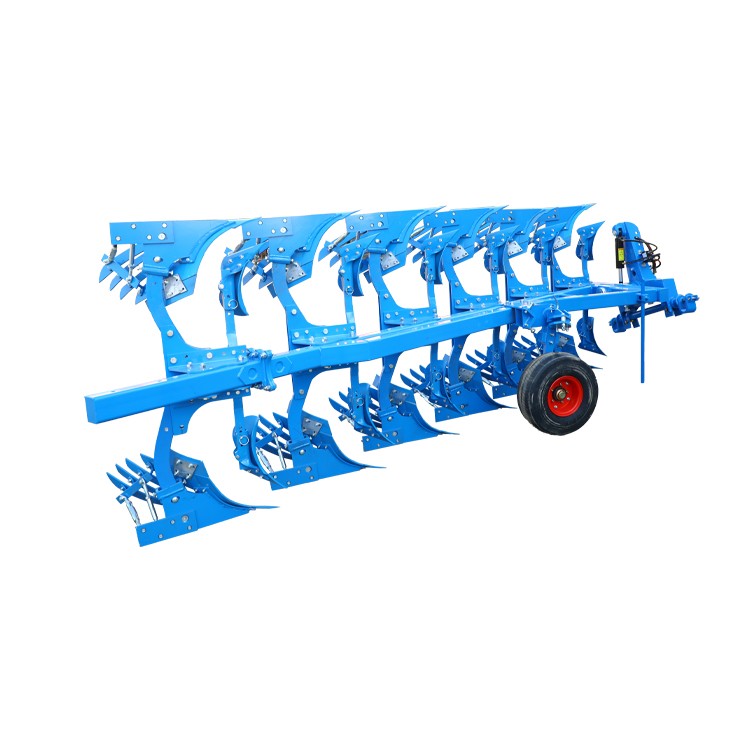

Key components of reversible plows

The plow consists of several basic components that work in concert with each other to achieve optimal tillage efficiency and quality. The main frame acts as the backbone of the reversible plough, supporting the weight of the plough body and other accessories. The headstock connects the plow to the tractor and houses the reversing mechanism, which allows the plow to rotate 180 degrees. Furrow wheels or depth control systems ensure consistency in plowing depth, while skimmers help bury surface vegetation to improve decomposition.

Working mechanism of reversible plow

Tillage process

The working mechanism of a reversible plow involves a series of coordinated actions that lead to effective soil turning and furrow formation. As the tractor moves forward, the plow cuts into the soil, creating a clean patch of land. The template then lifts and turns the soil sheet, turning it upside down and depositing it on the previously plowed furrow. This process continues along the length of the site, with each subsequent channel building on the previous one. The reversible design allows the operator to maintain a consistent plowing direction, eliminating the need for circular patterns or dead furrows characteristic of traditional plows.

Adjustment and fine tuning

For optimal performance, reversible plows need to be carefully adjusted and fine-tuned according to soil conditions and desired results. Furrow depth can be adjusted using a depth control wheel or hydraulic system to ensure consistent furrow depth across different terrains. The working width of each plow body can be modified to suit different tractor power output or soil type. The plow's widening system allows the operator to change the furrow width at any time to adapt to changing field conditions or specific crop requirements.

Benefits and considerations of using a reversible plow

The advantages of reversible farming

1. Bidirectional tillage reduces field preparation time and fuel consumption. This efficient operation improves the soil structure and reduces compaction, as the tractor's wheels are always running on unplowed land.

2. Plows create a flat field surface that facilitates subsequent operations such as seedbed preparation and planting.

3. The versatility of the reversible plow allows for efficient farming on irregularly shaped terrain where consistent furrow patterns can be maintained.

Challenges and limitations

The initial investment cost of a plow is usually higher than that of a traditional tool, which may be a consideration for small farming operations. The increased complexity of reversing mechanisms and add-ons may require more frequent maintenance and potential repairs. Operators need to be properly trained to effectively use and adjust reversible plows, as incorrect Settings can result in poor performance or soil damage. In very heavy or viscous soil conditions, the reversing mechanism may face additional pressure, which may affect the service life of the actuator.

Best practices for use

To maximize the benefits of a reversible plow and ensure its longevity, farmers should follow several best practices. Regular maintenance, including proper lubrication of moving parts and inspection of worn parts, is essential for optimal performance. The operator should carefully match the size and configuration of the plow to the tractor's power output and field conditions. Proper adjustment of working depth, trench width and skimmer Settings is essential to achieve the required soil inversion and residue management. When working in challenging soil conditions, gradually increasing the depth and carefully monitoring the plow's performance can help prevent excessive stress on the actuator and tractor. Finally, incorporating reversible farming into comprehensive soil management strategies, including crop rotation and conservation practices, can lead to long-term improvements in soil health and crop productivity.

The unique design and operation of the reversible plow offers many benefits, from reduced field preparation time to improved soil structure. Despite the challenges, properly implementing and managing reversible plows can significantly improve agricultural productivity and sustainability. If you would like to know more about this product, you can contact us at lucky@shuoxin-machinery.com