English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

- Boom Sprayer

- Air Blast Sprayer

- Lawn Mower

- Wheel Rake

- Land Leveler

- Fertilizer Spreader

- Manure Spreader

- Seeder Machine

- Agricultural Machinery Transmission Shaft

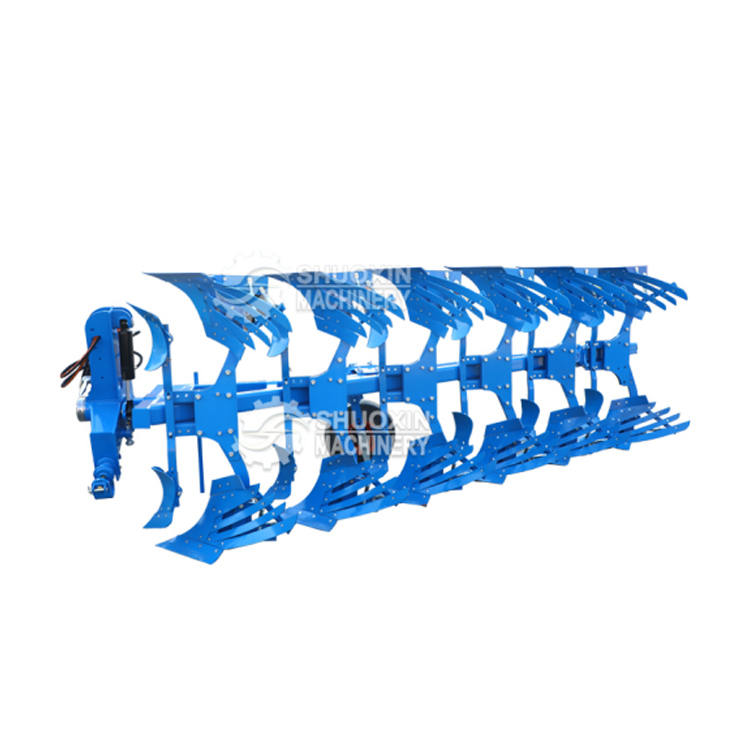

- Plow

- Automatic Roll Tube Sprayer

- Gear Pumps

- Hydraulic Valve

- Bundled Straw Net

- Tractor Flail Mower

- Seedling Killing Machine

- Rotary Rake

- Rake Sun

- Ridging Machine

- Rotary Tiller

Rotary Disc Mowers

Shuoxin is a research and development company focusing on handling and lifting machinery with a professional technical team and advanced production equipment, we ensure that the performance and quality of our rotary disc mowers reach the industry-leading level.

Send Inquiry

The rotary disc mowers are versatile and efficient agricultural implement designed to revolutionize the process of harvesting forage crops. This innovative machine combines the cutting power of a product with the conditioning capabilities of a hay conditioner, creating a powerful tool for farmers and ranchers.

Advantages of Using Shuoxin Rotary Disc Mowers

Enhanced Cutting Efficiency

Rotary disc mowers offer superior cutting efficiency compared to traditional sickle-bar mowers. The rapidly rotating discs equipped with multiple blades allow for a clean, precise cut even in dense or lodged crops. This increased efficiency translates to higher working speeds and greater overall productivity, enabling farmers to cover more acreage in less time. The disc design also minimizes the risk of clogging or plugging, which can be a common issue with other mower types, especially in wet or tangled crop conditions.

Improved Crop Conditioning

The conditioning component of the rotary disc mowers play a crucial role in accelerating the drying process of harvested forage. By crimping or crushing the plant stems, the conditioner creates small breaks in the waxy outer layer of the plant, allowing moisture to escape more rapidly. This process, known as conditioning, can significantly reduce drying time, sometimes by as much as 25-30%. Faster drying not only improves the overall quality of the hay by preserving more nutrients but also reduces the risk of weather-related damage during the curing process.

Versatility in Various Crop Conditions

Disc mower conditioners demonstrate remarkable adaptability across a wide range of crop types and field conditions. Whether dealing with thick, lush alfalfa or delicate grass mixtures, these machines can be adjusted to deliver optimal performance. Many models feature adjustable cutting heights, conditioning intensity, and swath width, allowing desired outcomes. This versatility makes the product conditioners suitable for use in diverse agricultural operations, from small-scale farms to large commercial hay producers.

Key Components of a Disc Mower Conditioner

Cutting System

The heart of the rotary disc mowers is cutting system, which consists of a series of circular discs mounted on a sturdy cutterbar. Each disc is equipped with multiple sharp, replaceable blades that rotate at high speeds to slice through crops cleanly and efficiently. The design of the cutting system allows for smooth, uninterrupted cutting action, even in challenging conditions such as lodged or tangled crops. Some advanced models feature quick-change blade systems, enabling operators to replace worn or damaged blades quickly and easily, minimizing downtime during critical harvest periods.

Conditioning Mechanism

Following the cutting process, the conditioning mechanism comes into play. There are typically two main types of conditioners: roller conditioners and flail conditioners. Roller conditioners use a pair of intermeshing rollers (often made of rubber or steel) to crimp and crack the plant stems. This method is particularly effective for legume crops like alfalfa, as it preserves leaf integrity while facilitating faster drying. Flail conditioners, on the other hand, use a series of rotating fingers or tines to scuff and break the waxy coating on plant stems. This approach is often preferred for grass crops and can be more aggressive in conditioning tough-stemmed plants.

Frame and Suspension System

The frame and suspension system of rotary disc mower are crucial for maintaining optimal cutting performance across varying field conditions. Many modern models feature a floating cutterbar design that allows the cutting unit to follow ground contours independently of the main frame. This design helps ensure a consistent cutting height and reduces the risk of scalping or leaving uncut areas in uneven terrain. Additionally, advanced suspension systems, often incorporating springs or hydraulic cylinders, provide the necessary flexibility to navigate obstacles and protect the machine from damage when encountering rocks or other field obstructions.

Maintenance and Care for Rotary Disc Mowers

Regular Inspection and Cleaning

Proper maintenance is essential for ensuring the longevity and optimal performance of the rotary disc mower. Regular inspections should be conducted to check for worn or damaged components, loose fasteners, and proper lubrication of moving parts. After each use, thorough cleaning is crucial to remove accumulated debris, plant material, and moisture that can lead to corrosion or impaired function. Particular attention should be paid to the cutting discs, blades, and conditioning mechanism, as these areas are most susceptible to wear and buildup of crop residue.

Blade Maintenance and Replacement

The cutting blades are a critical component of the disc mower and require regular attention to maintain peak performance. Operators should inspect blades frequently for signs of wear, damage, or dullness. Dull or damaged blades not only reduce cutting efficiency but can also increase fuel consumption and put additional stress on the machine's drive system. Many manufacturers recommend rotating or replacing blades after a certain number of acres or hours of operation. When replacing blades, it's important to use high-quality, OEM-approved parts to ensure proper fit and optimal cutting performance.

Off-Season Storage and Preparation

Proper storage during the off-season is crucial for protecting the disc mower conditioner from environmental damage and ensuring it's ready for the next harvest season. Before storage, the machine should be thoroughly cleaned and inspected for any worn or damaged parts that may need replacement. All exposed metal surfaces should be coated with a protective lubricant to prevent rust and corrosion. The machine should be stored in a dry, covered area, preferably on a level surface with the cutterbar slightly raised to relieve pressure on the suspension components. Prior to the next use, a comprehensive pre-season inspection and servicing should be performed, including checking and adjusting belt tensions, lubricating all grease points, and verifying proper hydraulic function.

Rotary disc mowers have revolutionized forage harvesting, offering unparalleled efficiency and versatility. By combining cutting and conditioning in one pass, these machines save time, preserve crop quality, and adapt to diverse field conditions. Proper maintenance ensures optimal performance and longevity, making disc mower conditioners an invaluable asset for modern agricultural operations. If you want to get more information about this product, you can contact us at mira@shuoxin-machinery.com.