English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

- Boom Sprayer

- Air Blast Sprayer

- Lawn Mower

- Wheel Rake

- Land Leveler

- Fertilizer Spreader

- Manure Spreader

- Seeder Machine

- Agricultural Machinery Transmission Shaft

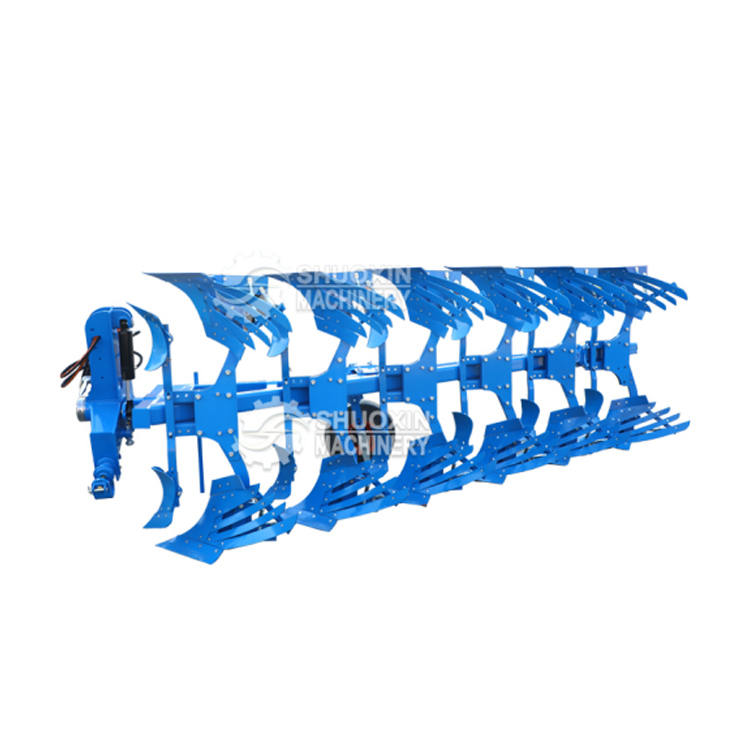

- Plow

- Automatic Roll Tube Sprayer

- Gear Pumps

- Hydraulic Valve

- Bundled Straw Net

- Tractor Flail Mower

- Seedling Killing Machine

- Rotary Rake

- Rake Sun

- Ridging Machine

- Rotary Tiller

Stainless Steel Fertilizer Spreaders

As a manufacturer of agricultural machinery integrating production and sales, the stainless steel fertilizer spreaders we produce have excellent performance, efficient operation ability and environmental protection design concept, specially for farmers to solve the problem of fertilizer spreaders.

Send Inquiry

To improve production efficiency and crop quality is the focus of every farmer, in order to help the majority of farmers more scientific and efficient farming, Shuoxin has produced an efficient and durable and accurate stainless steel fertilizer spreaders, which can promote the sustainable development of agricultural production, improve soil fertility and ensure the growth of crops.

Cleaning and inspection of stainless steel fertilizer spreaders

Thorough cleaning technology

Proper cleaning is the basis for maintaining stainless steel fertilizer spreaders. First remove all residual fertilizer from the hopper and distribution unit. Use a pressure washer and a mild detergent solution to remove stubborn deposits. Pay special attention to corners that are difficult to clean, as there may be residues of fertilizer. For complex parts, compressed air is used to remove particles from cracks and small openings. Make sure all moving parts, such as stirrers and dispersal trays, are thoroughly cleaned to prevent corrosion and keep running smoothly.

Detailed inspection process

After cleaning, do a thorough inspection of your stainless steel fertilizer spreaders. Check the hopper for signs of corrosion or structural damage. Check the integrity of welds and joints, as these areas are vulnerable to pressure and potential failures. Check the mixer for wear or dislocation, so as not to affect the normal flow of fertilizer. Check the diffuser disk carefully for any bent or damaged blades that may affect the distribution pattern. At the same time, do not neglect smaller components such as bearings, seals and fasteners, because their condition is crucial to the overall performance.

Identify common problems

In the inspection process, attention should be paid to the common problems of stainless steel fertilizer spreaders. Look for signs of cracks in the material, especially in areas affected by persistent vibration or load. Check the hopper or frame for deformation so as not to affect productivity or stability. Evaluate the condition of the metering system to ensure accurate flow control. Identify areas where any fertilizer buildup is recurring, as this could be because of design flaws or operational issues that need to be addressed.

Solve corrosion and wear problems

Despite the corrosion-resistant properties of stainless steel, planters can still wear out over time. A wire brush or a cleaning agent specifically designed for stainless steel can be used to carefully remove the corroded material and treat any corroded areas. For slight corrosion of the surface, it can be polished. In the case of more severe damage, welding or patching may be considered to restore the integrity of the component. And pay special attention to where different metals meet, because these joints are prone to galvanic corrosion.

①Three Point Hitch:Three point linkage tractor suspension

②PTO shaft:PTO shaft as power support

③201 Stainless Steel Hopper with treated with rust inhibitor

④Horizontal mixer to help the falling of fertilizer

⑤Stainless Steel Spreading Disc

⑥Adjustable Stainless Steel Fins

⑦Shielded front plate:to prevent spreading of material in front of spreader

⑧Adjustable positions:to obtain maximum spreading precision

If you met with some difficulties in the spreader problems, welcome to contact us: mira@shuoxin-machinery.com, we are committed to every user to provide a full range of pre-sale consulting, after-sales guidance and after-sales service. From stainless steel fertilizer spreaders purchase to installation and commissioning, and then to later maintenance, we have a professional team to follow up.