English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

- Boom Sprayer

- Air Blast Sprayer

- Lawn Mower

- Wheel Rake

- Land Leveler

- Fertilizer Spreader

- Manure Spreader

- Seeder Machine

- Agricultural Machinery Transmission Shaft

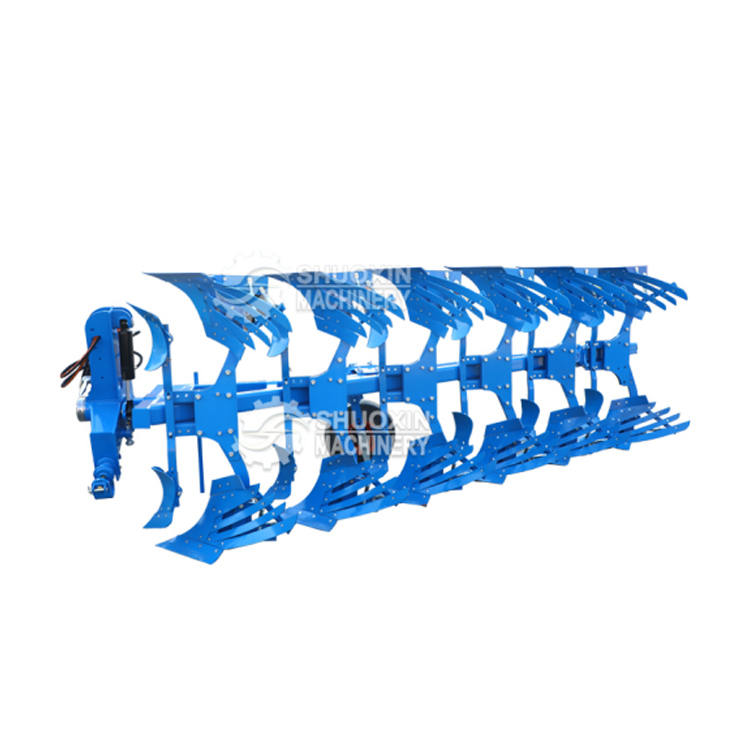

- Plow

- Automatic Roll Tube Sprayer

- Gear Pumps

- Hydraulic Valve

- Bundled Straw Net

- Tractor Flail Mower

- Seedling Killing Machine

- Rotary Rake

- Rake Sun

- Ridging Machine

- Rotary Tiller

Tractor Pto Drive Shaft

Baoding Shuoxin is an enterprise famous for producing tractor pto drive shaft and various kinds of agricultural machinery, with perfect testing equipment and strong technical force. Has been committed to a variety of high-quality agricultural machinery processing and production.

Send Inquiry

The tractor pto drive shaft the precision gear system mounted on the PTO shaft by cleverly utilizing the rotational power generated by the tractor's power output shaft, which creates specific vibration patterns when conducted on the shaft. These gears further convert the rotating power to the speed and torque required for the work of various agricultural machinery, so as to drive the working parts on various agricultural machinery such as harvesters, planters, rototillers, sprayers, such as blades, wheels, chains, etc., to achieve the effective and accurate transmission of power from tractors to agricultural machinery and then to specific working parts.

| SERIES | D(mm) | W(mm) | 540min | 1000min | ||||

| Cv | Kw | Nm | Cv | Kw | Nm | |||

| 1S | 22.0 | 54.0 | 16 | 12 | 210 | 25 | 18 | 172 |

| 2S | 23.8 | 61.3 | 21 | 15 | 270 | 31 | 23 | 220 |

| 3S | 27.0 | 70.0 | 30 | 22 | 390 | 47 | 35 | 330 |

| 4S | 27.0 | 74.6 | 35 | 26 | 460 | 55 | 40 | 380 |

| 5S | 30.2 | 80.0 | 47 | 35 | 620 | 74 | 54 | 520 |

| 6S | 30.2 | 92.0 | 64 | 47 | 830 | 100 | 74 | 710 |

| 7S | 30.2 | 106.5 | 75 | 55 | 970 | 118 | 87 | 830 |

| 8S | 35.0 | 106.5 | 95 | 70 | 1240 | 150 | 110 | 1050 |

| 9S | 41.0 | 108.0 | 120 | 88 | 1560 | 190 | 140 | 1340 |

| SERIES | D(mm) | W(mm) | 540min | 1000min | ||||

| Cv | Kw | Nm | Cv | Kw | Nm | |||

| 1S | 22.0 | 54.0 | 16 | 12 | 210 | 24 | 18 | 175 |

| 2S | 23.8 | 61.3 | 27 | 20 | 355 | 42 | 31 | 295 |

| 3S | 27.0 | 70.0 | 33 | 24 | 400 | 50 | 37 | 320 |

| 4S | 27.0 | 74.6 | 38 | 28 | 500 | 60 | 44 | 415 |

| 5S | 30.2 | 80.0 | 47 | 35 | 620 | 70 | 51 | 500 |

| 32S | 32.0 | 76.0 | 53 | 39 | 695 | 83 | 61 | 580 |

| 6S | 30.2 | 92.0 | 55 | 40 | 850 | 83 | 61 | 690 |

| SERIES | D(mm) | W(mm) | 540min | 1000min | ||||

| Cv | Kw | Nm | Cv | Kw | Nm | |||

| 6S | 30.2 | 92.0 | 55 | 40 | 850 | 83 | 61 | 690 |

| 7S | 30.2 | 106.5 | 75 | 55 | 1000 | 106 | 78 | 810 |

| 8S | 35.0 | 106.5 | 90 | 66 | 1250 | 136 | 100 | 1020 |

| 7NS | 35.0 | 94.0 | 70 | 51 | 970 | 118 | 87 | 830 |

| 36S | 36.0 | 89.0 | 90 | 66 | 1175 | 140 | 102 | 975 |

| 42S | 42.0 | 104.0 | 107 | 79 | 1400 | 166 | 122 | 1165 |

This process not only ensures the efficiency of power transmission, but also greatly improves the flexibility and versatility of agricultural machinery, making it easy for tractors to cope with a variety of complex farmland operating environments, and meet the efficient, accurate and diversified operation needs of modern agriculture.

Type and classification

Installation position:

Rear-mounted: Tractor pto drive shaft mounted on the rear of the tractor, is the most common form of tractor.

Front-mounted: This product installed in the front of the tractor, generally used for high-horsepower tractors, mainly for joint operations.

Side mounted: Located on the side of the tractor, it is usually used more on small horsepower tractors.

Speed characteristics:

Constant speed type: The speed of the power output shaft is in a fixed proportion to the engine speed, which is often used to drive harvesters, rotary tillers and fixed working machines.

Synchronous speed type: The speed of the power output shaft is in a fixed proportion to the speed of the tractor, which is often used to drive the seeder, fertilizer applicator, planting machine and the transaxle of the trailer.

Care and maintenance

1.Check the tractor pto drive shaft and its connecting parts regularly for wear, cracks, or other damage.

2.Check whether the fasteners of the products are firm, and tighten them in time if they are loose.

3.Clean the sliding surface of the machinery to reduce friction and wear.

4.Lubricate the sliding surfaces and bearings of the machinery to reduce wear and extend their service life. Use suitable lubricants and lubricate as recommended by the manufacturer.

5.If the parts of the machinery are found to be seriously worn or damaged, they should be replaced in time.